Inspections

Here you learn all about the technologies and processes Carbon Craft X use to inspect your bike.

All of our inspection techniques are NDT based (Non Destructive Testing) and carried out by experienced technicians.

Technologies / Methods Used

-

Ultrasonic Pulse Echo Inspection

Learn MoreWe use high tech ultrasonic flaw detection equipment to complete non-destructive test (NDT) to identify flaws in carbon fibre bike frames and components.

-

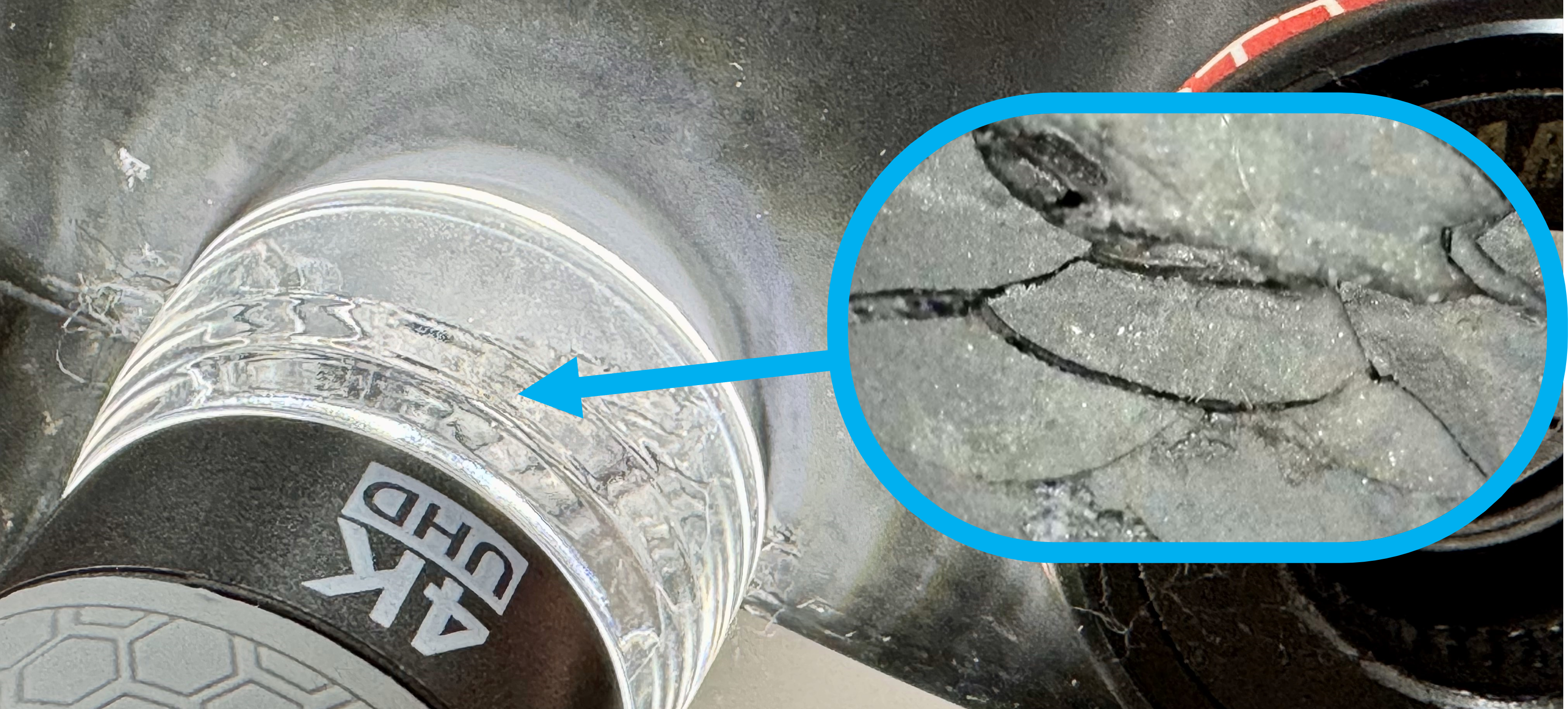

Digital Microscopy

Learn MoreWe use portable high definition digital microscopes to conduct visual inspections at 1000x magnification or more to examine damage that would otherwise be invisible to the human eye.

-

Digital Borescope

Learn MoreWe use ultra small industrial cameras previously only found in the medical industry to gain access through the smallest holes in the the frame to conduct internal inspections that would otherwise be impossible to see.

-

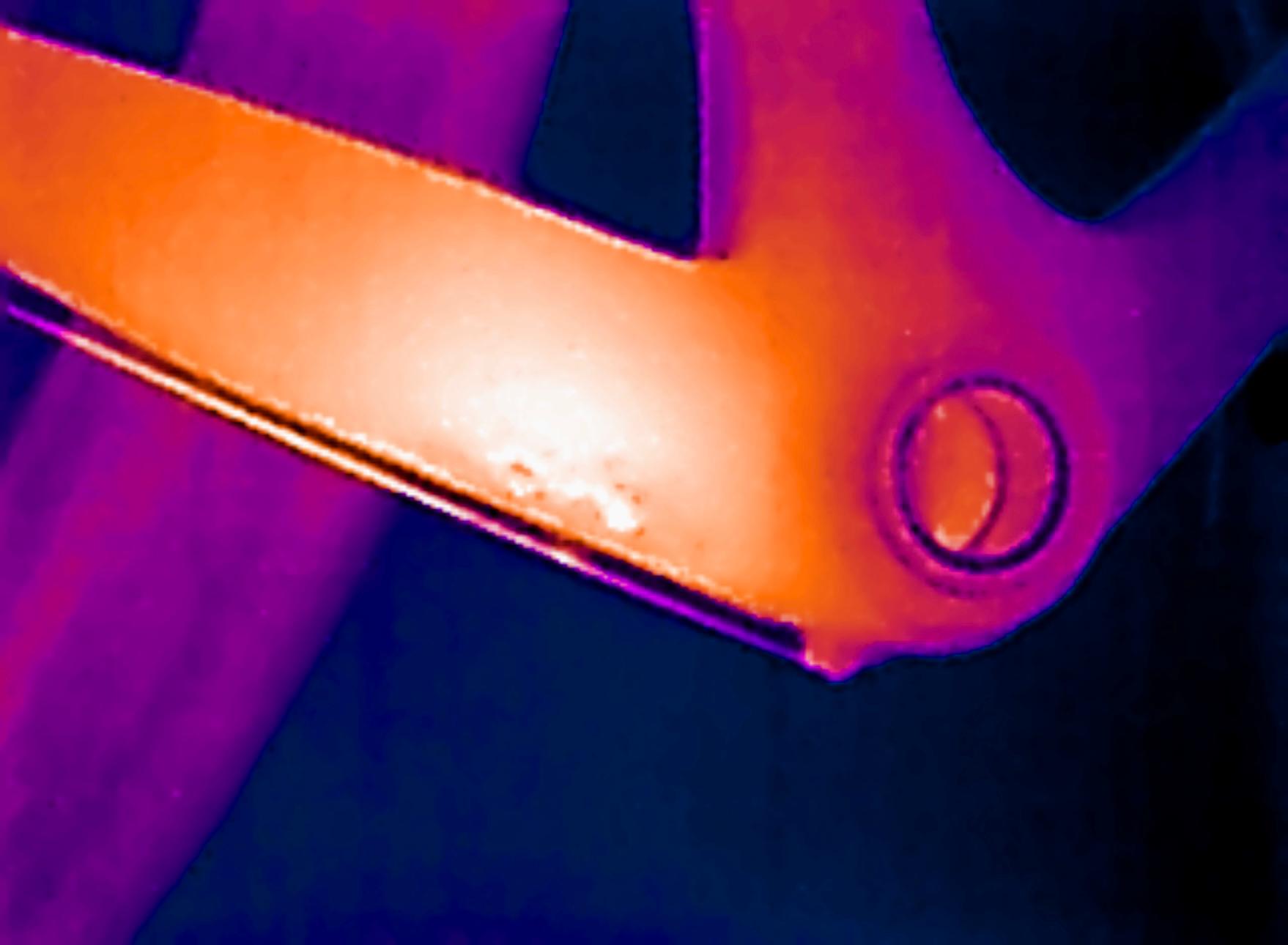

Active Thermography

Learn MoreWe use the latest thermal cameras and infrared heat sources to detect previous repairs & patch jobs you may not be aware of.

It can also be used to detect hidden / surface level defects like delaminations and voids that visual checks miss. -

Visual Inspection

Learn MoreOur trained and experienced technicians look over every millimeter of your bike to check for abnormalities and identify potential points of damage or interest for further inspection with our specialised equipment.

-

Stress / Flex Inspection

Learn MoreWe carefully conduct controlled flex / stress tests of key areas of the frame where we believe there may be a crack. Often a hairline crack can look like an innocuous scratch in the paintwork and can only be confirmed as serious damage through a stress / flex test.

-

Customer communication

Learn MoreEffective communication with customers is key to accurate carbon bike inspections. Understanding the incident, potential damage, and any unusual sounds or performance issues helps pinpoint problems and ensure a thorough, reliable assessment.

What is Non-Destructive Testing (NDT)?

NDT stands for non-destructive testing and is also known as non-destructive examination (NDE), non-destructive inspection (NDI) and non-destructive evaluation (NDE).

Non-destructive testing (NDT) is a testing and analysis technique used by industry to evaluate the properties of a material, component, structure or system for characteristic differences or welding defects and discontinuities without causing damage to the original part.

Ultrasonic Pulse Echo Inspection

Why do we use ultrasonic pulse echo testing ?

Ultrasonic pulse echo testing (UPET) is the industry leading method for inspecting carbon fiber frames and components due to its exceptional accuracy, instant results, and completely non-destructive and safe nature.

At Carbon Craft X, we have made significant investments in advanced equipment and expertise to introduce this aerospace-standard testing technique to the cycling industry.

How does ultrasonic testing work

Sound waves are powerful tools for precision testing, traveling through materials (in our case, carbon fiber) at specific speeds and frequencies based on their unique properties.

At the heart of our process, ultrasonic flaw detectors generate detailed waveforms that our skilled experts analyze to pinpoint and classify any imperfections with unmatched accuracy.

This cutting-edge technique uses proven reference standards and industry-approved procedures to distinguish flawless components from potential defects.

With ultrasonic testing, you gain the confidence of reliable, non-destructive insights, ensuring the highest quality for your bike.

Piezoelectric Crystal Technology

At the testing head (transducer) of our ultrasonic equipment is a piezoelectric crystal element coupled with advanced electronics.

It works by applying ultra high speed pulses of electricity to a crystal which causes it to vibrate. These vibrations / pulses travel through the material and return back to the the crystal. The crystal vibrates again upon the return of the pulse which generates an electric signal.

Using high speed processing, complex algorithms, and careful calibration of transmission speed within the medium being tested, it is possible to very accurately determine the thickness of the material and / or the depth of any cracks / defects within the material.

Digital Microscopy

Why do we use digital microscopy ?

We use portable high definition digital microscopes to conduct visual inspections at 1000x magnification or more to examine damage that would otherwise be invisible to the human eye or other traditional methods.

How does digital microscopy work ?

High quality digital cameras are used in combination with specialised microscope lenses to make an ultra portable and easy to maneuver microscope that allows our technicians to view every part of a bike in complete detail that would otherwise not be possible with the naked human eye.

Digital Borescope

Why do we use digital borescopes ?

A digital borescope is the ultimate tool for inspecting the interior of a carbon bike frame, offering unparalleled precision and convenience.

Its high-resolution camera allows for a clear, detailed view of hard-to-reach areas, ensuring that even the smallest cracks, delaminations, or irregularities are detected.

Unlike traditional methods, a digital borescope is non-invasive and completely safe for delicate carbon structures.

This advanced technology saves time, enhances accuracy, and provides peace of mind that every inch of the frame has been thoroughly inspected.

How do digital borescopes work ?

Cutting edge ultra small high quality digital cameras are used in combination with very long but narrow flexible tubes that fit into the smallest of spaces and are easy to maneuver.

The real-time video feed and ability to capture images make it easy to document findings and communicate them with customers or team members.

Active Thermography

Why do we use active thermography ?

Active thermography is particularly good at detecting previous repairs & patch jobs.

It can also be used to detect hidden / surface level defects like delaminations and voids that visual checks miss.

It’s non-destructive and highly effective since carbon fiber’s low thermal conductivity makes flaws easy to spot with infrared imaging.

How does active thermography work ?

The process involves applying heat to the bike frame and using an infrared camera to track how it dissipates. Defective areas heat and cool differently, revealing structural issues without damaging the bike.

Visual Inspection

Visual inspection as a fundamental starting point

To start the process of inspection our technicians will start with a detailed visual inspection to identify all areas of interest for further inspection.

A small detail such as a paint chip on the bicycle frame could indicate a crack, so visual inspections are useful for detecting delaminations at the surface and edges of materials.

Stress / Flex Inspection

Stress / Flex Testing

Stress or flex tests are crucial for verifying damage on carbon fiber bikes because visual inspections alone cannot always reveal internal or structural issues.

Carbon fiber is designed to distribute forces efficiently, meaning cracks or delaminations may not visibly surface even after significant impacts.

By applying controlled stress or flex to the frame or components, these tests can expose hidden weaknesses or confirm their integrity.

This ensures that any damage compromising safety or performance is identified and addressed, providing riders with confidence in their bike's reliability.

Stress testing is an essential step in ensuring accurate diagnoses and maintaining the highest safety standards for carbon fiber bikes.

Customer Communication

Clear and open communication

Clear, open and honest communication with customers is essential for accurately inspecting their carbon fiber bikes. Understanding the incident that occurred—whether it was a crash, impact, or unusual stress—helps identify the potential damage type, its extent, and likely location.

Details such as strange noises, changes in performance, or anything unusual the rider has noticed provide valuable clues that guide a thorough inspection.

By collaborating with customers, we ensure no detail is overlooked, allowing for precise diagnostics and reliable recommendations to keep their bikes safe and performing at their best.

Whatsapp us!

Whatsapp us!